Choosing between denier and tex depends on your project needs. If you need a lightweight, soft fabric, denier measures fiber thickness and strength for delicate materials like hosiery. For heavier, more durable textiles, tex is better as it focuses on weight per 1,000 meters of fiber. Understanding these differences helps you select the right measurement for your fabric’s strength and weight. Keep exploring to learn how each measurement impacts your textile choices.

Key Takeaways

- Use denier for lightweight, delicate fabrics like hosiery; opt for tex for heavier, industrial textiles.

- Lower denier (15-30) indicates finer, softer fibers; higher denier (70-100) suggests thicker, more durable fibers.

- Tex measures overall fabric weight, ideal for durability-focused applications like workwear.

- Match measurement units to project needs: finer fibers for comfort, heavier for strength and longevity.

- Understanding these differences ensures proper fiber selection for optimal fabric performance and project success.

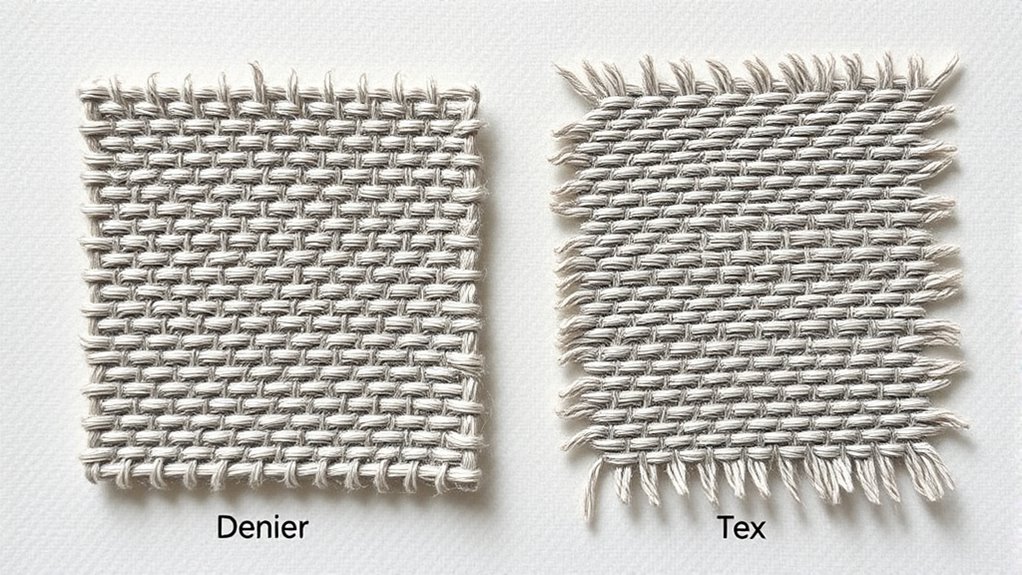

Have you ever wondered what the difference is between denier and tex when it comes to measuring fabric thickness? These two units are essential for understanding the qualities of textiles, but they serve different purposes and can notably impact your project. Denier measures the mass in grams of 9,000 meters of fibers, mainly used for finer fabrics like hosiery or silk. Tex, on the other hand, measures the mass in grams of 1,000 meters of fiber, making it more suitable for heavier or thicker materials. Additionally, fabric measurement units like denier and tex are crucial for ensuring the right specifications for your textile needs.

Choosing between denier and tex depends on what you’re aiming for in your project. If you’re working with lightweight, delicate fabrics, denier provides a clear indication of fiber thickness and strength. A lower denier number, such as 15 or 30, suggests a finer, softer fabric, often with less fiber strength but more flexibility. Conversely, higher denier counts, like 70 or 100, indicate thicker fibers that are more durable and resistant to wear. When selecting fabric, consider fiber strength because it directly influences material durability. Stronger fibers withstand tension, abrasion, and environmental stress better, which is vital for items like outdoor gear or upholstery.

Lower denier fabrics are finer, softer, and less durable, ideal for delicate textiles and fashion items.

Tex measurement is more straightforward for heavier fabrics since it reflects the actual weight per unit length. If you’re designing workwear or industrial textiles, understanding tex helps you choose materials with the right durability and thickness for demanding conditions. Heavier tex counts typically mean more material per meter, which translates to greater durability and a sturdier feel. This makes tex ideal when material robustness is a priority, especially in projects that require long-lasting, tough textiles.

It’s also worth noting that the choice between denier and tex can influence production and cost. Denier’s focus on fiber strength and finesse makes it popular in fashion and specialty textiles, where fine details matter. Tex, emphasizing weight and durability, suits industrial applications where material robustness is key. When selecting your fabric, consider the end-use—whether you need a lightweight, flexible material or a heavy-duty, resilient one—and choose the measurement unit that best aligns with these needs. Ultimately, understanding the differences helps you make informed decisions, ensuring your project has the right balance of fiber strength and material durability for successful results.

Frequently Asked Questions

How Does Environmental Impact Differ Between Denier and Tex?

When comparing denier and tex, you should consider their environmental impacts. Tex generally involves larger fiber measurements, which can mean using more raw materials, potentially impacting sustainability. Denier, focusing on finer fibers, might use less material, supporting eco-friendly manufacturing practices. Your goal should be to balance durability with sustainability considerations, choosing the measurement that minimizes environmental impact while meeting your project’s needs.

Are There Specific Fabrics Better Suited for Denier or Tex?

Imagine creating something durable yet lightweight—your fabric type and textile weight matter. For projects needing strength, thicker fabrics like canvas or denim suit higher denier measurements, while lighter, delicate fabrics like silk or chiffon align better with tex. You’ll find that sturdy, heavy fabrics excel with denier, while finer, more flexible textiles work best with tex. Choosing the right measurement guarantees your project’s fabric type matches its purpose perfectly.

Can I Convert Measurements From Denier to Tex Easily?

Converting measurements from denier to tex is straightforward with some quick calculations, fitting within textile standards. To do a measurement conversion, you divide the denier value by 9 to get the tex value. Keep in mind, textile standards recommend understanding these conversions to guarantee your fabric selection matches your project needs. Always double-check your calculations for accuracy, especially when switching between these two measurement systems.

How Do Denier and Tex Affect Fabric Durability?

You’ll find that denier and tex influence fabric durability through fiber strength and dye absorption. Higher denier or tex generally means thicker fibers, making the fabric stronger and more resistant to wear. This thickness also affects dye absorption, resulting in richer, more vibrant colors. So, choosing the right measurement helps guarantee your fabric’s durability aligns with your project’s needs, whether you prioritize strength or color intensity.

Which Measurement Is More Industry Standard Today?

Think of the industry as a shifting tide—you might wonder whether denier or tex is more standard today. Currently, tex is gaining ground because it better reflects fiber flexibility and dye absorption, making it more versatile for diverse fabrics. While denier remains popular, tex’s precision helps manufacturers produce consistent, high-quality textiles. So, if you’re aiming for industry relevance, tex is often the go-to measurement now.

Conclusion

Now that you’ve seen the differences between denier and tex, you’re better equipped to choose the right measurement for your project. Remember, picking the wrong one can be like fitting a square peg in a round hole—your results won’t be as expected. Trust your needs and don’t be afraid to dig a little deeper. With the right info in hand, you’ll be able to weave your project smoothly, like a well-oiled machine ready to go.