Lab-grown leather is nearing the point where mass production could become feasible, as researchers are making progress with cultivation techniques and bioreactor improvements. However, significant manufacturing challenges, like maintaining consistent quality and reducing costs, still exist. While it’s not widely available yet, ongoing technological advances are bringing scalable, commercial options closer. If you want to discover how these innovations might shape the future of sustainable materials, there’s more to explore below.

Key Takeaways

- Technological advances in bioreactors and cultivation methods are improving quality and scalability.

- Manufacturing processes are still experimental, facing challenges in consistency and large-scale production.

- Current costs remain higher than traditional leather, limiting mass-market affordability.

- Ongoing innovations aim to automate and standardize production, moving toward commercial viability.

- Broader adoption depends on overcoming manufacturing hurdles, reducing costs, and increasing production capacity.

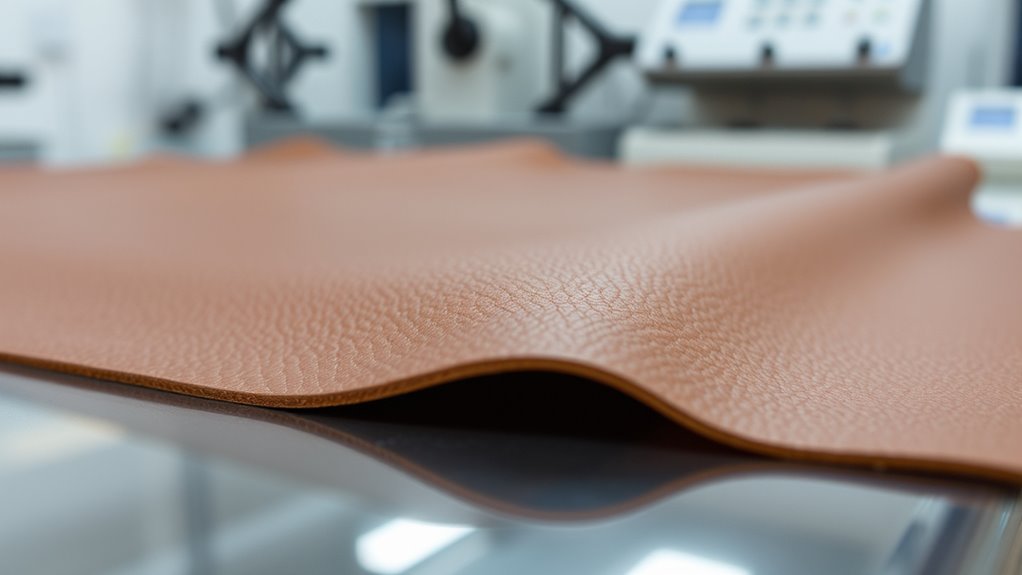

Have you ever wondered if there’s a more sustainable alternative to traditional leather? Lab-grown leather, also known as cultivated or cultured leather, promises to offer an eco-friendly option that avoids many environmental issues tied to animal farming. It’s made by growing collagen or other similar proteins in controlled environments, mimicking the texture and appearance of natural leather without the need for raising animals or harvesting hides. This innovation appeals to consumers seeking sustainable alternatives, but whether it’s ready for mass production depends on a range of factors, including manufacturing challenges and technological advancements.

One of the biggest hurdles facing lab-grown leather is scaling up production. Currently, most manufacturing processes are still in the experimental or small-scale phase, and shifting to large-scale manufacturing presents significant challenges. Producing lab-grown leather requires sophisticated bioreactors, precise control over growth conditions, and high-quality raw materials, all of which add complexity and cost. Ensuring consistent quality across large batches is another challenge, as variations in the cultivation process can affect texture, durability, and appearance. These manufacturing challenges make it difficult to produce lab-grown leather at the volume and price points necessary to compete with traditional leather on a mainstream level.

Scaling up lab-grown leather remains challenging due to complex manufacturing processes and quality consistency issues.

Cost remains a major obstacle as well. While prices have decreased over the past few years, lab-grown leather still tends to be more expensive than conventional options due to the complexity of production and the relatively nascent state of the technology. For widespread adoption, manufacturing processes need to become more efficient and cost-effective. Additionally, companies must develop sustainable and scalable supply chains for the raw materials used in cultivation, which can be resource-intensive themselves. Advances in bioreactor technology are expected to help address some of these cost and scalability issues moving forward.

Despite these challenges, progress is steady. Researchers and startups are continually refining cultivation techniques, reducing production costs, and improving the quality of lab-grown leather. Innovations in bioreactor design, automation, and standardization are helping to address manufacturing challenges. As these technologies mature, you can expect lab-grown leather to become more accessible, opening up new opportunities for brands and consumers enthusiastic to embrace sustainable fashion.

Frequently Asked Questions

What Are the Environmental Impacts of Lab-Grown Leather Production?

You might wonder about the environmental impacts of lab-grown leather production. It generally involves sustainable practices, which reduce land use and animal waste. However, it still consumes resources like energy and water, and the manufacturing process may generate emissions. While it’s more eco-friendly than traditional leather, you should consider ongoing improvements to minimize resource consumption and maximize its positive environmental effects.

How Does the Cost of Lab-Grown Leather Compare to Traditional Leather?

Like comparing apples to oranges, the cost of lab-grown leather is currently higher than traditional leather. You’ll find that market pricing for lab-grown options is still in the early stages, often making it more expensive due to production scale and technology costs. However, as production ramps up and technology advances, expect the cost comparison to narrow, potentially making lab-grown leather a more affordable and sustainable alternative in the future.

Are There Any Health Concerns Associated With Lab-Grown Leather?

You might wonder if lab-grown leather poses health risks. Currently, it has low allergenic risks because it’s made from controlled environments, reducing the chance of contaminants. However, chemical exposure is a concern if harsh chemicals are used during production. It’s important to guarantee proper regulation and testing, so you can confidently use lab-grown leather without worry about skin reactions or chemical hazards.

How Durable Is Lab-Grown Leather Compared to Authentic Leather?

Durability, durability, durability—you want to know if lab-grown leather lasts. Through rigorous durability testing, you’ll find that lab-grown leather often matches or even exceeds authentic leather in material longevity. It withstands wear and tear, resisting cracking and peeling. While some may worry about its strength, ongoing innovations are boosting its toughness. Overall, lab-grown leather proves to be a durable, dependable alternative that can stand the test of time and daily use.

What Are the Current Challenges in Scaling up Production?

You face challenges in scaling up lab-grown leather due to complex scaling logistics and maintaining quality consistency. As production increases, managing supply chains becomes more difficult, and ensuring each batch meets high standards is vital. These issues can slow down mass production, requiring innovations in manufacturing processes and tighter quality controls. Overcoming these hurdles is essential for making lab-grown leather a viable, sustainable alternative on a large scale.

Conclusion

Lab-grown leather is finally stepping out of the laboratory and into the spotlight, ready to take on mass production. It’s like a seed that’s just begun to sprout, promising a more sustainable future for fashion. While challenges remain, this innovative material has the potential to revolutionize the industry and reduce environmental impact. The question isn’t if it will succeed, but when you’ll start seeing it in your favorite stores—ready to change the way you style your world.