Supreme Fabric's revolutionizing the textile industry by using cutting-edge technology to produce high-quality narrow fabrics for automotive, medical, and apparel sectors. They focus on customer-specific needs and invest in advanced solutions for superior fabric performance. While tackling sustainability challenges like recycling inefficiencies and economic hurdles, Supreme Fabric remains committed to innovation. Their approach aligns with market trends driven by streetwear and collaborations, paving the way for future growth. There's more to uncover about their impact and initiatives.

Key Takeaways

- Supreme Fabric leverages advanced technology to produce high-quality narrow fabrics tailored for automotive, medical, and apparel industries.

- The company prioritizes sustainability by addressing challenges in recyclable materials and developing mono-material fabrics for efficient recycling.

- Automation and Industry 4.0 innovations enhance production efficiency, reducing costs and improving operational competitiveness.

- Collaborations with luxury brands and artists in streetwear elevate fashion trends, influencing consumer demand for unique designs.

- Future growth is supported by a projected 7.4% CAGR in the global textile market, driven by sustainable and fashionable product preferences.

The Role of Supreme Fabric in the Narrow Fabrics Market

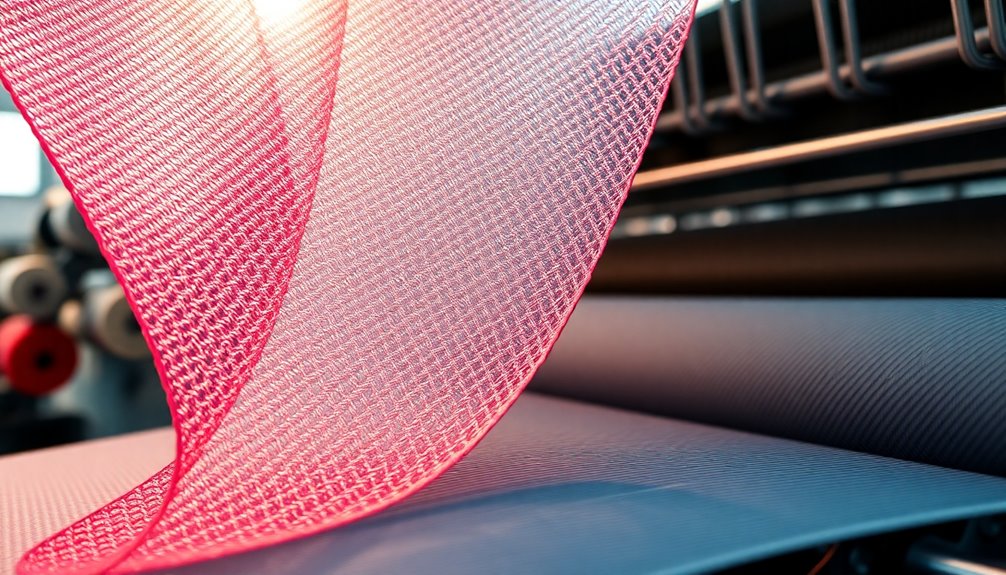

In the narrow fabrics market, Supreme Fabric plays a pivotal role by leveraging advanced technology and innovation to meet diverse industry needs. The company produces high-quality narrow fabrics tailored for various applications, including the automotive, medical, and apparel sectors. With a commitment to customization, you'll find that Supreme Fabric focuses on customer-specific requirements, ensuring their products, like tapes, webbings, and cords, meet exacting standards. Their investment in technical advancements leads to superior fabrics, enhancing performance while addressing industry demands. As the global market grows, particularly in the Asia Pacific region, Supreme Fabric is well-positioned to capitalize on the rising demand and contribute to the evolution of narrow fabrics in the narrow fabrics sector innovative and meaningful ways.

Addressing Sustainability Challenges in the Textile Industry

While tackling sustainability challenges in the textile industry, it's important to recognize the complex interplay of material, technological, economic, and regulatory factors.

You face hurdles like developing recyclable materials that maintain quality and the need for mono-material fabrics to streamline recycling. Additionally, inefficient recycling technologies and inadequate infrastructure hinder effective waste management. Effective sorting technologies are essential to address contamination issues that impact recycling efficiency.

Economically, circular fashion processes struggle against traditional models, requiring significant investment.

Socially, low wages and unsafe conditions complicate the shift toward sustainable practices.

Regulatory gaps can stifle innovation, making it imperative to advocate for policies like Extended Producer Responsibility.

Ultimately, fostering consumer awareness and promoting a cultural shift toward valuing longevity in clothing are significant steps in overcoming these sustainability challenges.

Technological Innovations Driving Production Efficiency

Technological innovations are reshaping the textile industry, driving production efficiency like never before. By embracing automation, you can enhance production speed and lower costs through machinery that effortlessly adapts to various products.

The rise of Industry 4.0 integrates digital technologies, streamlining manufacturing processes and boosting competitiveness. Software Quality Assurance empowers you to make informed decisions, reducing potential losses. Furthermore, the Circuline Innovation Lab demonstrates a commitment to integrating sustainable practices within manufacturing.

Design thinking encourages collaboration between designers and manufacturers, minimizing future issues. Additionally, virtual and augmented reality enhance both production processes and product design.

Upgrading equipment and optimizing processes cuts waste, enabling data-driven decisions that improve supply chain management. Overall, these innovations provide a competitive edge while promoting sustainability and market expansion.

Market Trends: Influences From Streetwear and Collaborations

As streetwear continues to reshape the fashion landscape, its influence on market trends is undeniable. You can see how brands like Supreme blur the lines between high fashion and urban culture, while collaborations with luxury houses elevate streetwear's global status. Supreme's collaborations with luxury brands like Louis Vuitton have particularly showcased this blending of styles, further solidifying its presence in the luxury market.

Limited-edition releases create exclusivity, driving demand and hype among consumers enthusiastic to showcase their style. This cultural phenomenon extends beyond fashion; it permeates music and art, resonating with diverse audiences.

Collaborations with artists further enhance streetwear's relevance, pushing innovative designs that redefine trends. As the hype culture grows, owning exclusive items becomes a status symbol, fostering community among enthusiasts and fueling a thriving resale market.

You can't ignore how streetwear has transformed consumer behavior and brand dynamics.

Commitment to Sustainability and Circular Economy Initiatives

The rise of streetwear hasn't only changed consumer preferences but also sparked a broader conversation about sustainability in the textile industry. You'll find that Supreme Industries is deeply committed to renewable energy, aiming for 75 million renewable energy units by 2025 and 97 million by 2030. They're enhancing their solar generation capacity and sourcing energy through power purchase agreements. Fast fashion's impact on waste management emphasizes the importance of excessive production in driving companies like Supreme to adopt sustainable practices. With regard to circular economy practices, the Circuline Innovation Lab focuses on developing sustainable materials, utilizing 80% recycled mono-polymer in products like the UniLoop Lamp. Supreme Industries effectively manages 93% of its manufacturing waste, ensuring all plastic is recycled.

Future Growth Prospects and Industry Challenges

While the textile industry faces numerous challenges, it also stands on the brink of significant growth. The global market, valued at USD 1837.27 billion in 2023, is projected to grow at a 7.4% CAGR through 2030. You'll see technological advancements, like Big Data and modern machinery, enhancing operations and competitiveness. Consumer demand is shifting towards fashionable and sustainable products, further fueling growth. Additionally, the global industrial protective clothing fabrics market is expected to grow at a CAGR of 8.1% from 2024 to 2034. Currency fluctuations can also impact the cost of imported raw materials, adding another layer of complexity to the industry's growth.

However, supply chain disruptions, raw material fluctuations, and environmental concerns pose significant hurdles. Additionally, data management issues can hinder efficiency. To thrive, you'll need to embrace Industry 4.0 technologies and focus on innovation, especially in protective clothing and geotextiles, to navigate these challenges and seize emerging opportunities.

Frequently Asked Questions

What Types of Narrow Fabrics Does Supreme Textiles Produce?

Supreme Textiles produces a range of narrow fabrics tailored for various applications.

You'll find rapier loom woven slit fabric, ideal for flexibility, and needle insertion loom woven fabric, perfect for narrow widths.

Shuttle loom woven fabric offers dimensionally stable options, while polypropylene-based fabrics are strong and durable for packaging.

Additionally, you can explore cotton, polyester, and nylon tapes commonly used in webbing and tape products.

Each type serves specific needs in the textile industry.

How Does Supreme Textiles Ensure Product Quality and Durability?

To guarantee product quality and durability, you perform rigorous inspections at every stage. You test fiber content, evaluate tensile strength, and assess colorfastness.

During manufacturing, you conduct in-process checks and monitor machine settings. After production, you run performance tests for moisture control and abrasion resistance.

You also establish clear quality standards and integrate customer feedback to continually improve. Your commitment to quality is reflected in the durable fabrics you produce.

What Is the Company's Approach to Customer Service?

Imagine a world where every customer feels valued and understood—this is what great customer service aims for.

Your company's approach centers on empathy and proactive support, anticipating your needs before they arise. They prioritize transparency, ensuring you always know what to expect.

With a customer-centric focus, they personalize interactions based on your history. Regular feedback means they're continually improving, ultimately building trust and ensuring satisfaction with every experience you have.

Where Are Supreme Textiles' Manufacturing Facilities Located?

Supreme Nonwoven Group's manufacturing facilities are primarily located in India, where you'll find 14 different facilities spread across various regions.

They also have two facilities in Thailand, supporting their expansion in Southeast Asia.

This geographic distribution allows you to access a diverse range of nonwoven products, ensuring that they can meet global market demands effectively.

Their presence in these locations helps strengthen their overall manufacturing footprint and supply chain capabilities.

How Does Supreme Textiles Engage With the Community?

Imagine you're at a modern-day community fair, and you see Supreme Textiles actively engaging with locals.

They partner with local organizations, run workshops to enhance skills, and support environmental initiatives.

You'll notice their employees volunteering, showcasing a commitment to social responsibility.

Through educational programs and scholarships, they empower the next generation.

Supreme's transparency in reporting their efforts guarantees you're always in the loop about their community impact.

It's a win-win for everyone involved!

Conclusion

In the ever-evolving tapestry of the textile industry, Supreme Fabric stands out as a vibrant thread weaving sustainability, innovation, and market trends together. By embracing technology and circular economy initiatives, you're not just keeping pace with changes—you're leading the way. As streetwear culture continues to influence design, the future looks bright. So, let's stitch together a more sustainable and efficient industry, ensuring every fabric is a step toward a greener tomorrow.